Aquaculture

Aquaculture is the cultivation and farming of aquatic organisms; be it fish, shellfish, crustaceans or algae.

Researchers at Aura CDT are exploring whether mussel farms and seaweed farms can benefit from colocation within the wind farms.

Colocation with commercial users

Wind farm operators must liaise with commercial neighbours and joint tenants operating in the area.

The impacts of offshore wind on the marine industries can be direct, as for example, impacts on fisheries, or it can be much broader from cultural and environmental aspects of society to policy decisions, flow of capital and supply and demand of labour.

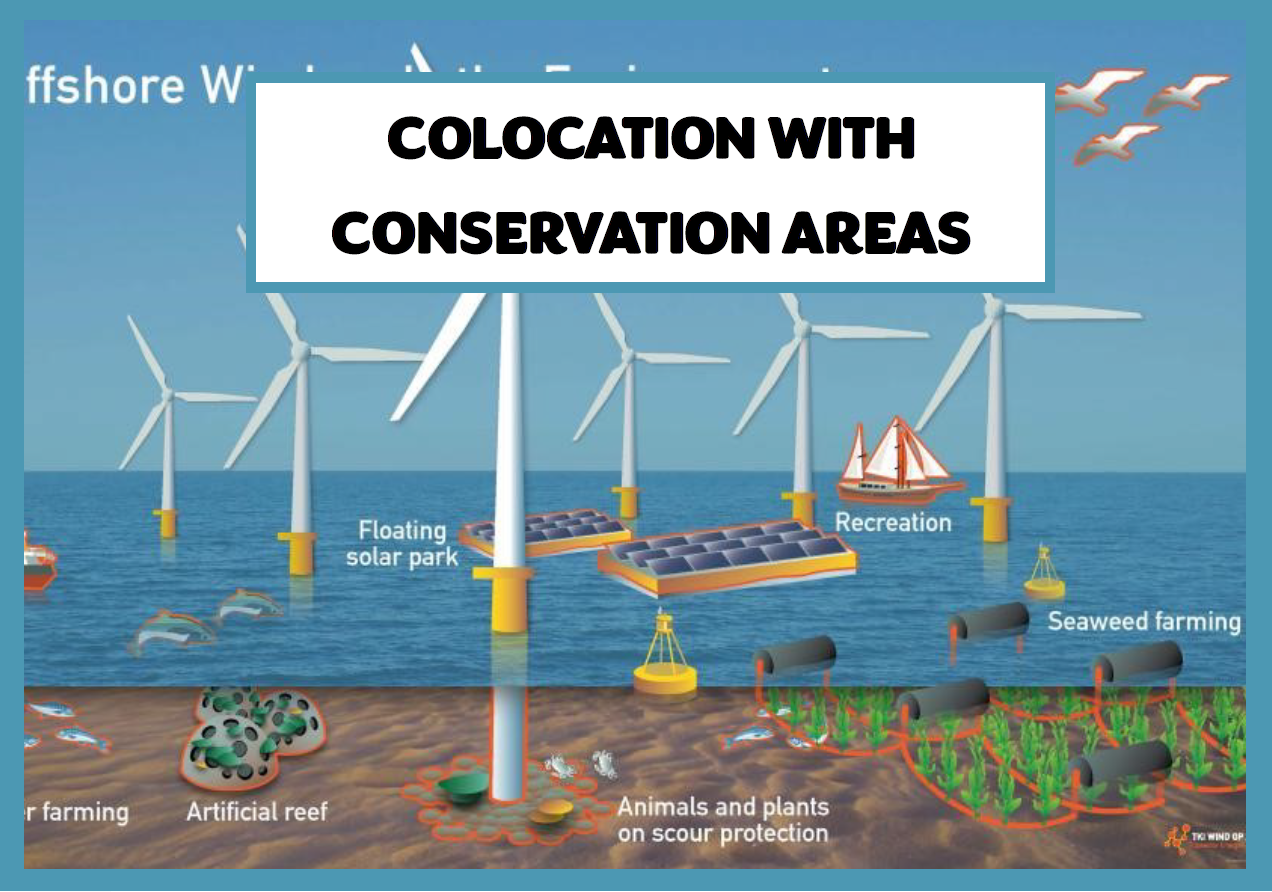

Colocation with conservation areas

Ensuring that the environment of a wind farm is not detrimentally affected is a legal obligation. This is especially important for protected areas.

The researchers can employ satellite data to monitor how the existing wind farms affect natural habitats.

Digital twins for blade factory

Grid Integration

Location and type of the connection of the wind farm to the national grid must be considered alongside the balance of electricity supply and demand.

One way to even out the differences in supply and demand is to connect to the wider electricity grid and create a super grid. A digital twin for the grid system could help prevent issues quicker and improve reliability and safety.

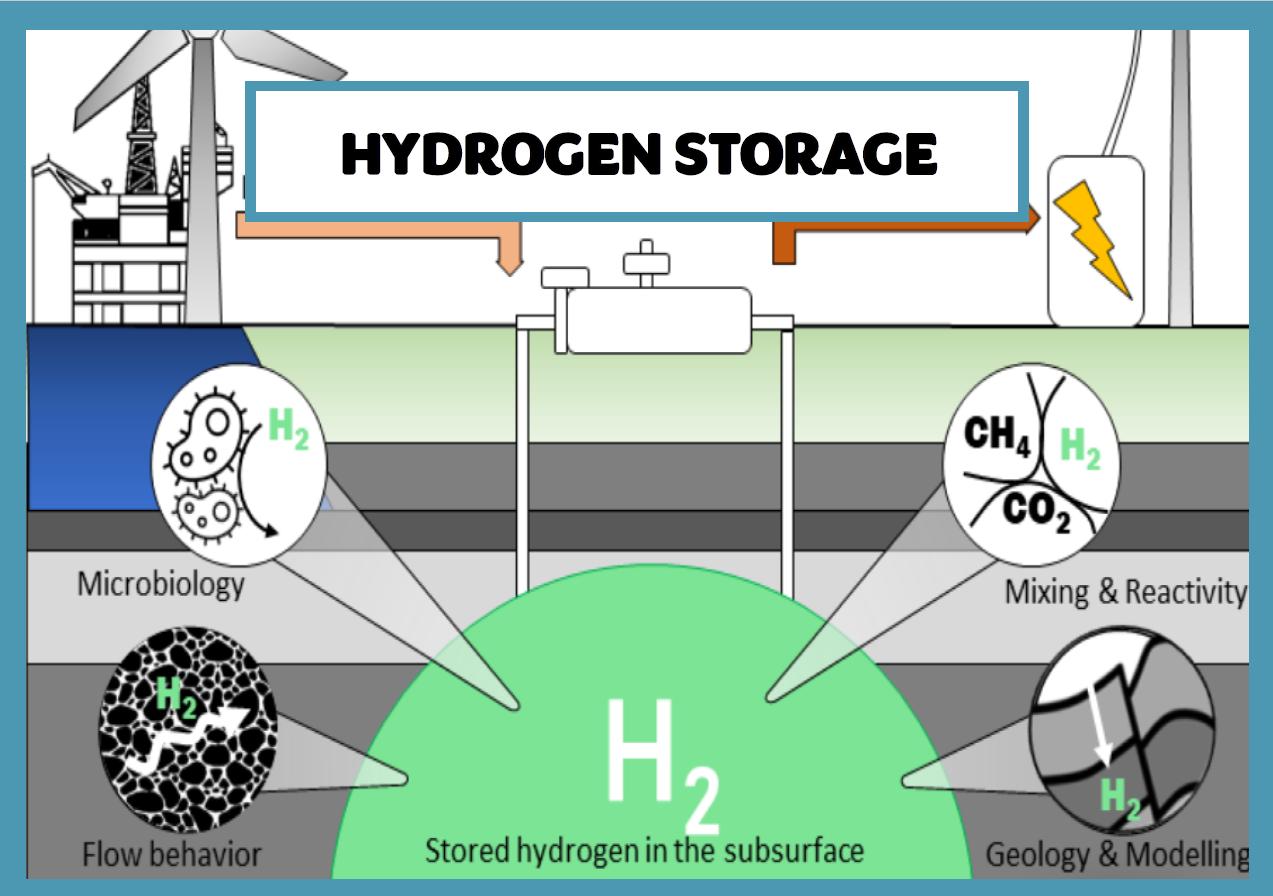

Hydrogen storage

Excess energy can be used to produce hydrogen which can later be used for power generation during peak periods. Hydrogen produced with electricity from renewable sources is called green hydrogen.

This technology is still very expensive and can be improved through research. For example, hydrogen generation could be combined with plastic generation, could be made more efficient by improving electrolysis process or integrating the storage into the wind turbine structure.

Improving blade design

Blades manufacture is one of the most labour-intensive processes in a wind farm. At the same time, blades are the hardest components to recycle.

This can be improved by producing the blades from recycled materials such as textiles, making the blade itself recyclable and improving the balance between the cost and performance of the blades.

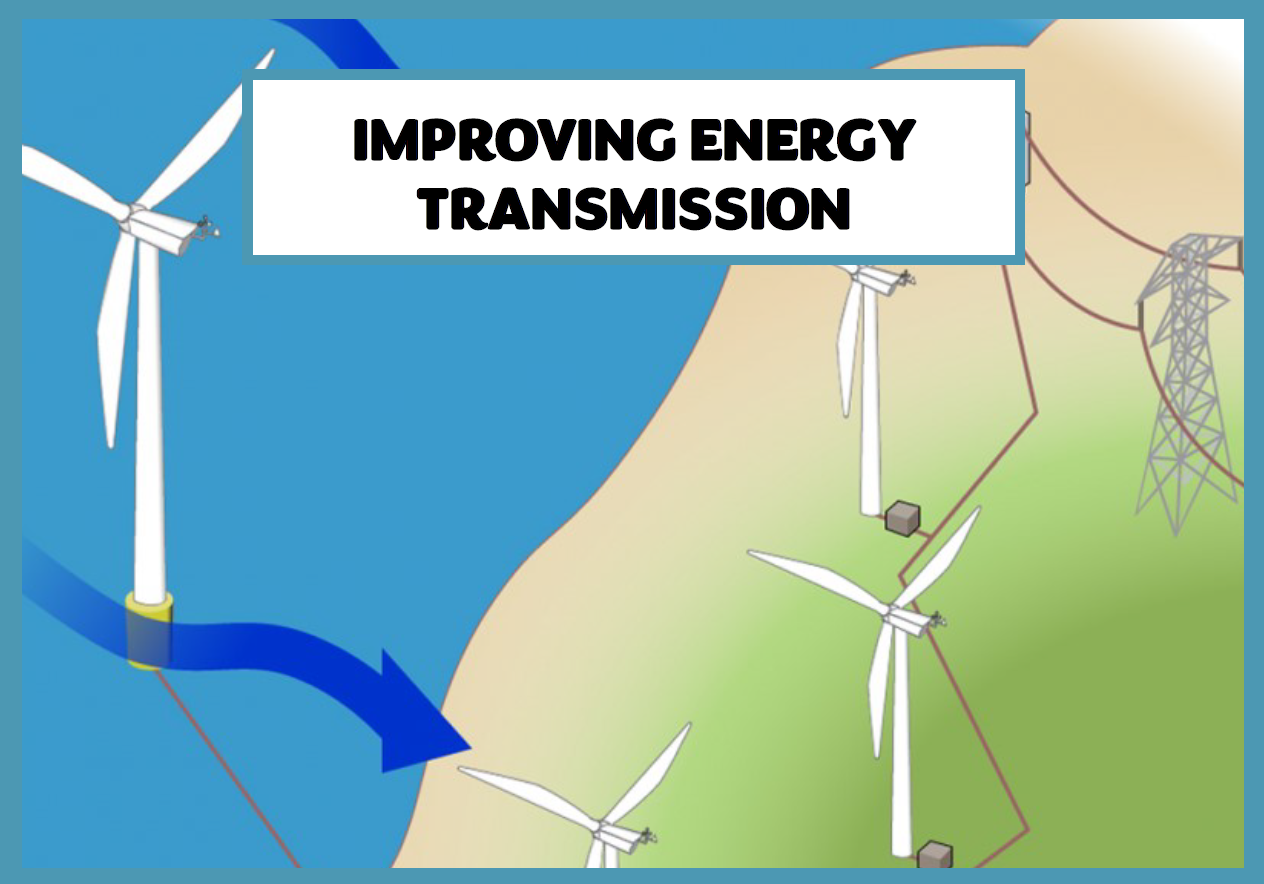

Improving energy transmission

Improving energy transmission is important because export cable failures are expensive and future wind farms will put more demand on cables.

Wireless power transmission is part of the Aura CDT research.

Improve manufacturing quality control

There are parameters that can be monitored to ensure that the product is manufactured to the required quality every time.

A researcher at Aura CDT studies how manufacturers can monitor and improve wind turbine blade production.

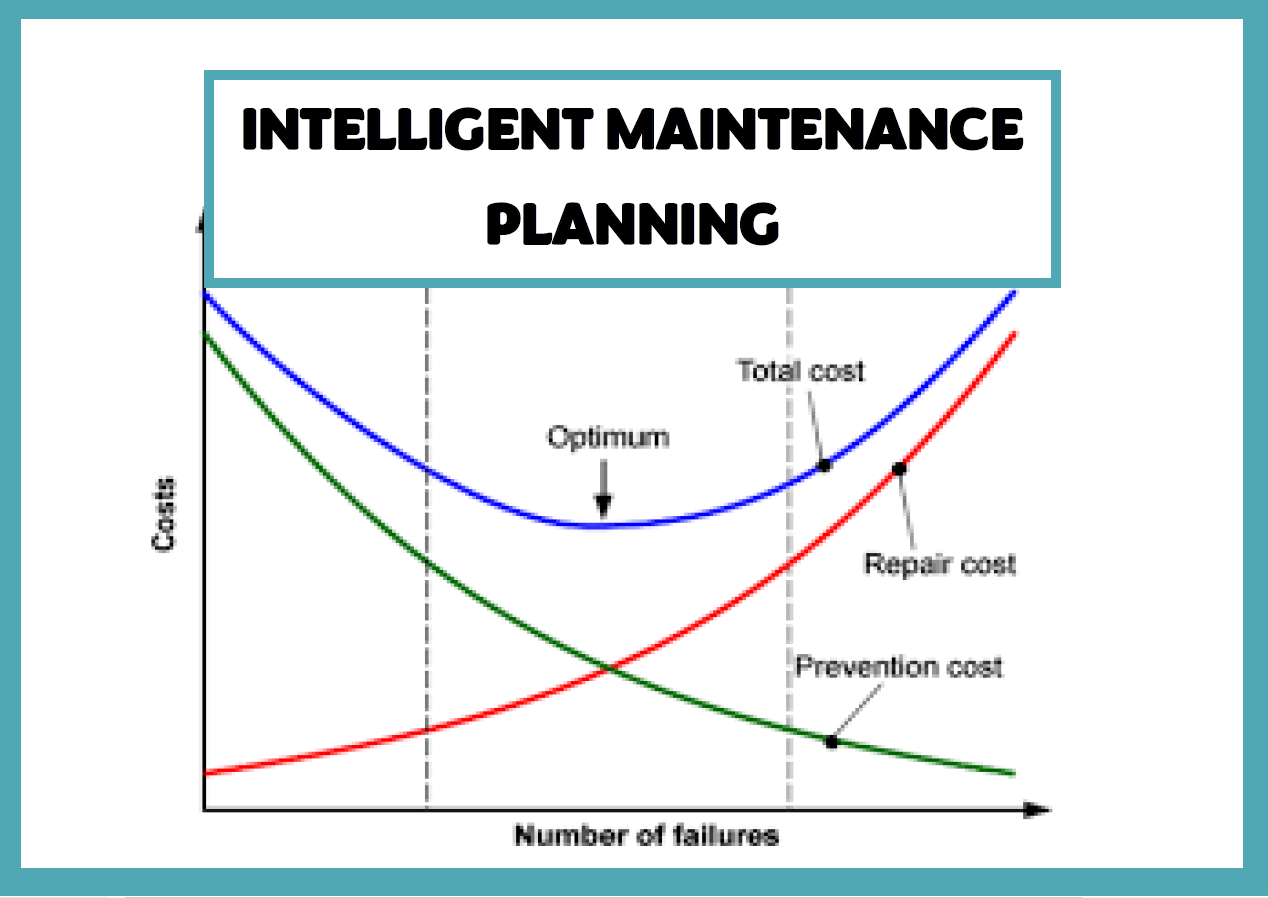

Intelligent maintenance planning

Sending people to wind farms takes time, money and poses a risk. Resource allocation and completion of tasks can be optimised.

These optimisations can be carried out by predicting potential failure or by building a digital twin of a turbine.

Monitoring the wind farm

Monitoring of different components of turbines, as well as cables and substations can help repairing the parts before they fail.

Monitoring data can be used in assessing the blades’ health. Sarah, Simon, David, Harry and Adam at Aura CDT are researching AI applications for blade monitoring. Other important parts to monitor are cables and generators.

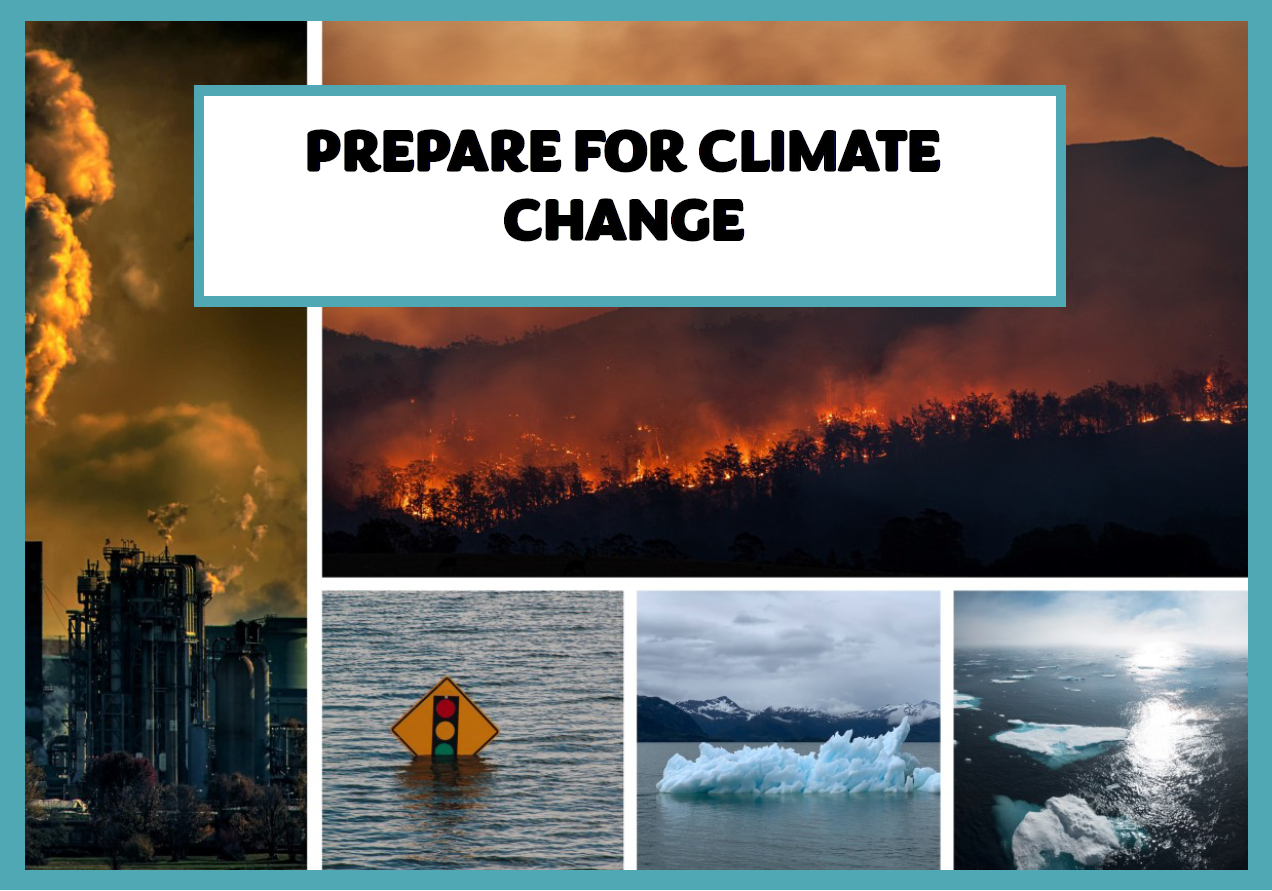

Prepare for climate change

Climate change can impact all stages of the offshore wind industry. These impacts need to be studied so that the industry can adapt.

This is part of ongoing research at Aura CDT.

For an informal discussion, call +44 (0) 1482 463331

or contact auracdt@hull.ac.uk